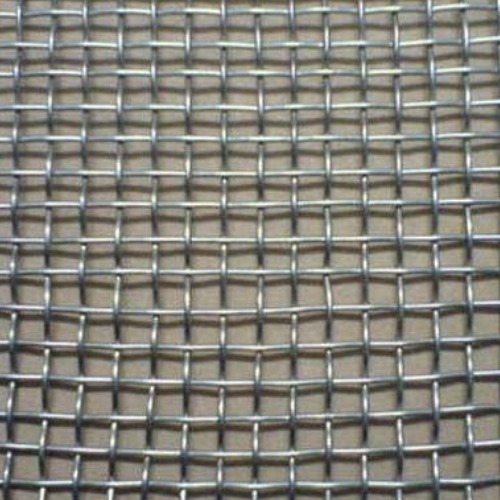

CRIMP WIRE MESH Pre-crimping wire enables the mesh to lock together, creating a tight weave with good rigidity and pleasing aesthetics. It is used extensively in architectural applications, as infill panels, cages and decoration. It is also used in acoustics, filtration, bridge guards, aerospace parts, rodent control, and truck grills. Crimping is a method used to create waves on any ductile material that has a straight surface such as steel or stainless steel alloys. Ductility aids the manufacturer in getting a distinct shape for a Crimped Wire Mesh . Used heavily in the mining industry, the material used to manufacture them is usually very durable. And since vibrations are a result of mining operations the alloys need to be able to withstand high levels of shock and vibrations. There are various methods used by Crimped Wire Mesh Manufacturers including double crimping, intermediate, flat top as well as lock crimping. While the most common use of the Stainless Steel Crimped Wire Mesh is in the field of mining, the other applications of the mesh include its use as a protective fence for stairs or equipment. Most applications require structures that have stability in order to successfully complete a run of the application. Amongst the four crimp types, the most stable variety is the Lock Crimp Wire Mesh because the structure of the crimp is what gives it stability because on each side of the raised wire there is a wire that is pressed against it creating a stable lock structure. On the other hand, a Double Crimped Wire Mesh has a rigid construction with a tight mesh structure. This structure is also commonly known as a plain weave wire mesh. To get accurate crimping, the wires are put through a pre-crimping process. The accuracy of the pre-crimping process is such that the wires used to make a Crimped Mesh will have a snug fit or will lock themselves at the appropriate intersections. Used For Brass Crimped Wire Mesh Filtering Sizing Grading Separating Shifting Screening Cages Guards Trays Partitions Poultry protection Concrete reinforcement Grid window Rack Lift Building construction Paving

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2024-05-09T10:23:53

CRIMP WIRE MESH Pre-crimping wire enables the mesh to lock together, creating a tight weave with good rigidity and pleasing aesthetics. It is used extensively in architectural applications, as infill panels, cages and decoration. It is also used in acoustics, filtration, bridge guards, aerospace parts, rodent control, and truck grills. Crimping is a method used to create waves on any ductile material that has a straight surface such as steel or stainless steel alloys. Ductility aids the manufacturer in getting a distinct shape for a Crimped Wire Mesh . Used heavily in the mining industry, the material used to manufacture them is usually very durable. And since vibrations are a result of mining operations the alloys need to be able to withstand high levels of shock and vibrations. There are various methods used by Crimped Wire Mesh Manufacturers including double crimping, intermediate, flat top as well as lock crimping. While the most common use of the Stainless Steel Crimped Wire Mesh is in the field of mining, the other applications of the mesh include its use as a protective fence for stairs or equipment. Most applications require structures that have stability in order to successfully complete a run of the application. Amongst the four crimp types, the most stable variety is the Lock Crimp Wire Mesh because the structure of the crimp is what gives it stability because on each side of the raised wire there is a wire that is pressed against it creating a stable lock structure. On the other hand, a Double Crimped Wire Mesh has a rigid construction with a tight mesh structure. This structure is also commonly known as a plain weave wire mesh. To get accurate crimping, the wires are put through a pre-crimping process. The accuracy of the pre-crimping process is such that the wires used to make a Crimped Mesh will have a snug fit or will lock themselves at the appropriate intersections. Used For Brass Crimped Wire Mesh Filtering Sizing Grading Separating Shifting Screening Cages Guards Trays Partitions Poultry protection Concrete reinforcement Grid window Rack Lift Building construction Paving

2024-05-09T10:23:53

Keywords

- run

- side

- waves

- order

- wires

- field

- shock

- panels

- stairs

- result

- snug fit

- accuracy

- equipment

- Ductility

- stability

- acoustics

- other hand

- filtration

- decoration

- common use

- structures

- vibrations

- tight weave

- high levels

- Crimped Mesh

- truck grills

- bridge guards

- good rigidity

- crimping wire

- lock crimping

- stable variety

- distinct shape

- rodent control

- aerospace parts

- various methods

- mining industry

- double crimping

- crimping process

- ductile material

- four crimp types

- protective fence

- Trays Partitions

- straight surface

- accurate crimping

- Most applications

- mining operations

- other applications

- rigid construction

- Poultry protection

- pleasing aesthetics

- tight mesh structure

- Lock Crimp Wire Mesh

- stable lock structure

- plain weave wire mesh

- intermediate, flat top

- Screening Cages Guards

- stainless steel alloys

- Double Crimped Wire Mesh

- appropriate intersections

- architectural applications

- Building construction Paving

- Crimped Wire Mesh Manufacturers

- Stainless Steel Crimped Wire Mesh

- Concrete reinforcement Grid window Rack Lift

- Brass Crimped Wire Mesh Filtering Sizing Grading

Submit Your Enquiry