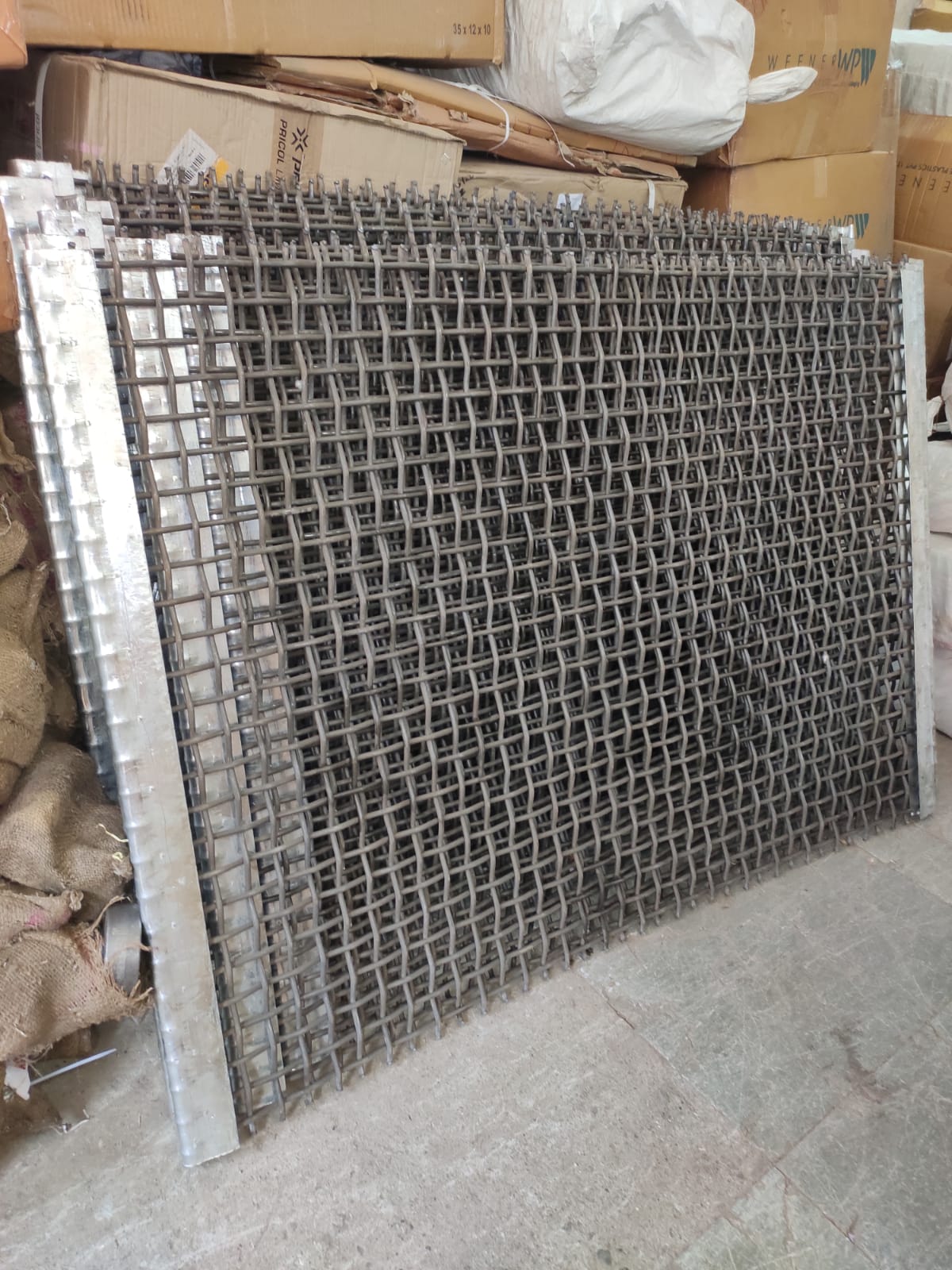

Wire Mesh

Laktas wire cloth is highly useful in filtration industries because it provides a reliable, durable, and customizable solution for separating solids from liquids or gases. Its precision, material strength, and adaptability contribute significantly to maintaining product quality, enhancing operational efficiency, and reducing overall filtration costs in various industrial sectors

1. Precise and Consistent Filtration:

• Controlled Mesh Sizes: Laktas manufactures wire cloth with precise and uniform mesh openings. This allows for highly accurate filtration, ensuring that only particles of a specific size are removed, while desired materials pass through. This is crucial for industries where product purity and quality are paramount (e.g., food and beverage, pharmaceuticals, chemicals).

• Wide Range of Micron Ratings: They can produce filter discs with sieve thicknesses ranging from 10 to 1000 microns, and wire mesh with various mesh sizes (e.g., 0-10 per inch for general industrial use, up to very fine meshes for ultra-fine filtration). This versatility caters to diverse filtration needs, from coarse screening to very fine separation of sub-micron particles.

2. Durability and Resistance:

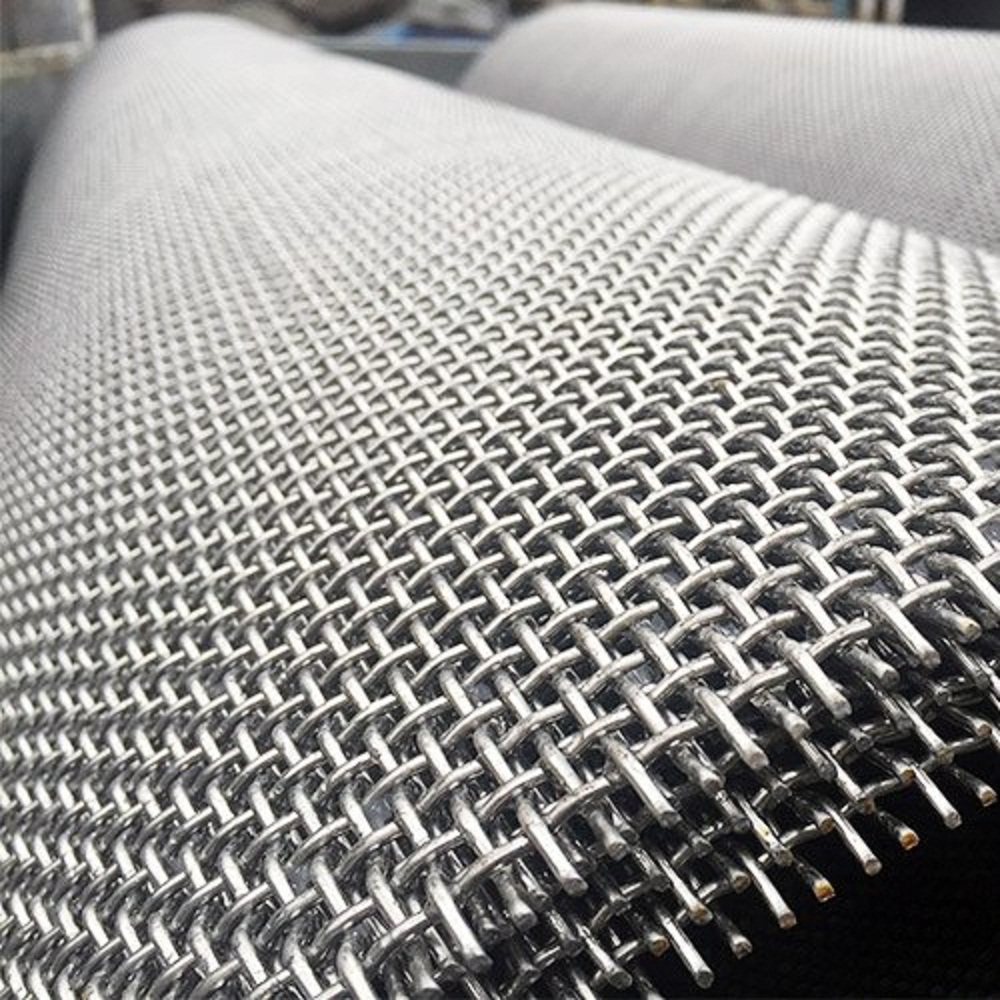

• Material Strength: Laktas wire cloth is primarily made from stainless steel (e.g., SS 304, SS 316), as well as other corrosion-resistant alloys. This provides high tensile strength, making the filters robust and capable of withstanding various impurities, fluctuating pressures, and extreme temperatures without compromising filtration accuracy or structural integrity.

• Corrosion Resistance: The use of stainless steel and other suitable metals makes the wire cloth highly resistant to corrosion, which is vital in industries dealing with aggressive chemicals, acidic or alkaline liquids, or harsh environments. This extends the lifespan of the filter and reduces replacement costs.

• Longevity: High-quality wire cloth is designed for durability and longevity, leading to reduced downtime for maintenance and replacements, thereby improving operational efficiency.

3. Versatility and Customization:

• Diverse Applications: Laktas wire cloth is used in a wide range of filtration applications, including liquid filtration (e.g., in chemical, pigment, food, and pharmaceutical sectors), gas filtration, and separation processes. They also supply products like demister pads, which are specifically designed for efficient liquid and gas separation.

• Customization: Laktas offers customization options for wire diameter, mesh openings, material types, and dimensions, allowing businesses to tailor filtration solutions to their specific requirements. This ensures optimal performance for unique filtration challenges.

• Various Weave Types: They produce different weave types (e.g., plain weave, crimped wire mesh) to suit specific filtration needs, impacting strength, opening size, and flow characteristics.

4. Efficiency and Cost-Effectiveness:

• Enhanced Flow Rate: The ability to customize wire diameter and mesh openings allows for optimal flow rates, maximizing the surface area for filtration and improving the efficiency of the filtration process.

• Easy Cleanability: The precise pore openings in wire mesh filters help reduce blinding and plugging, making them easier to clean and maintain, which ensures sustained efficiency.

• Long-Term Savings: Investing in durable and reliable Laktas wire cloth can lead to long-term cost savings by minimizing waste, improving product yield, and reducing maintenance and replacement expenses.

Send Message