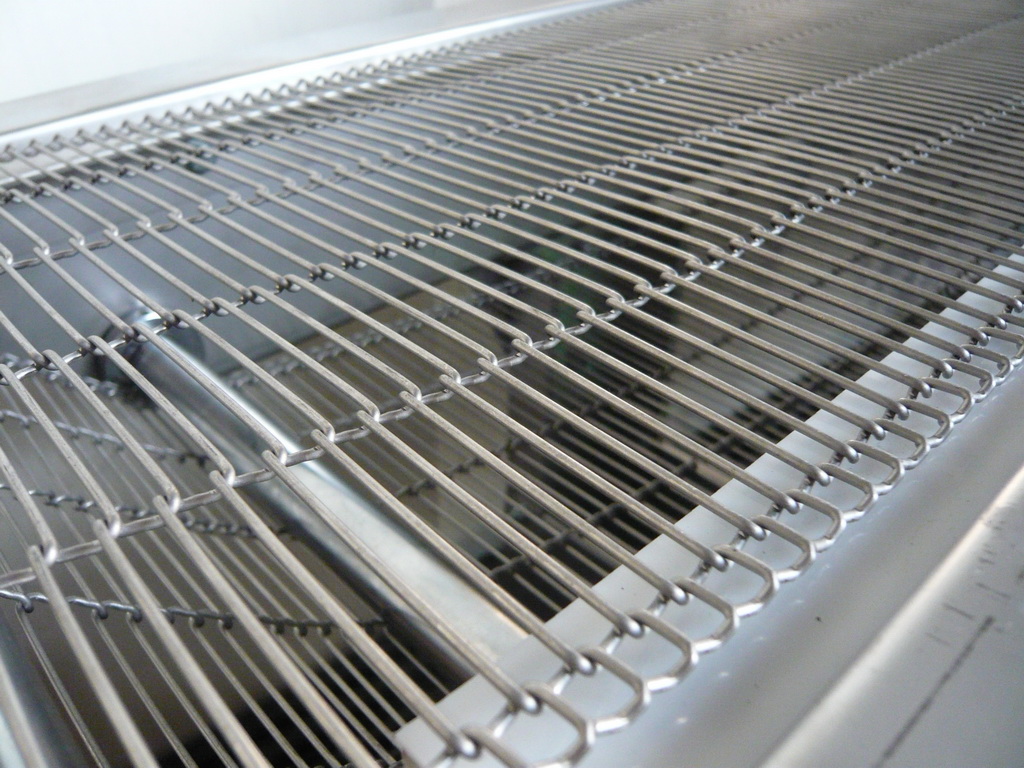

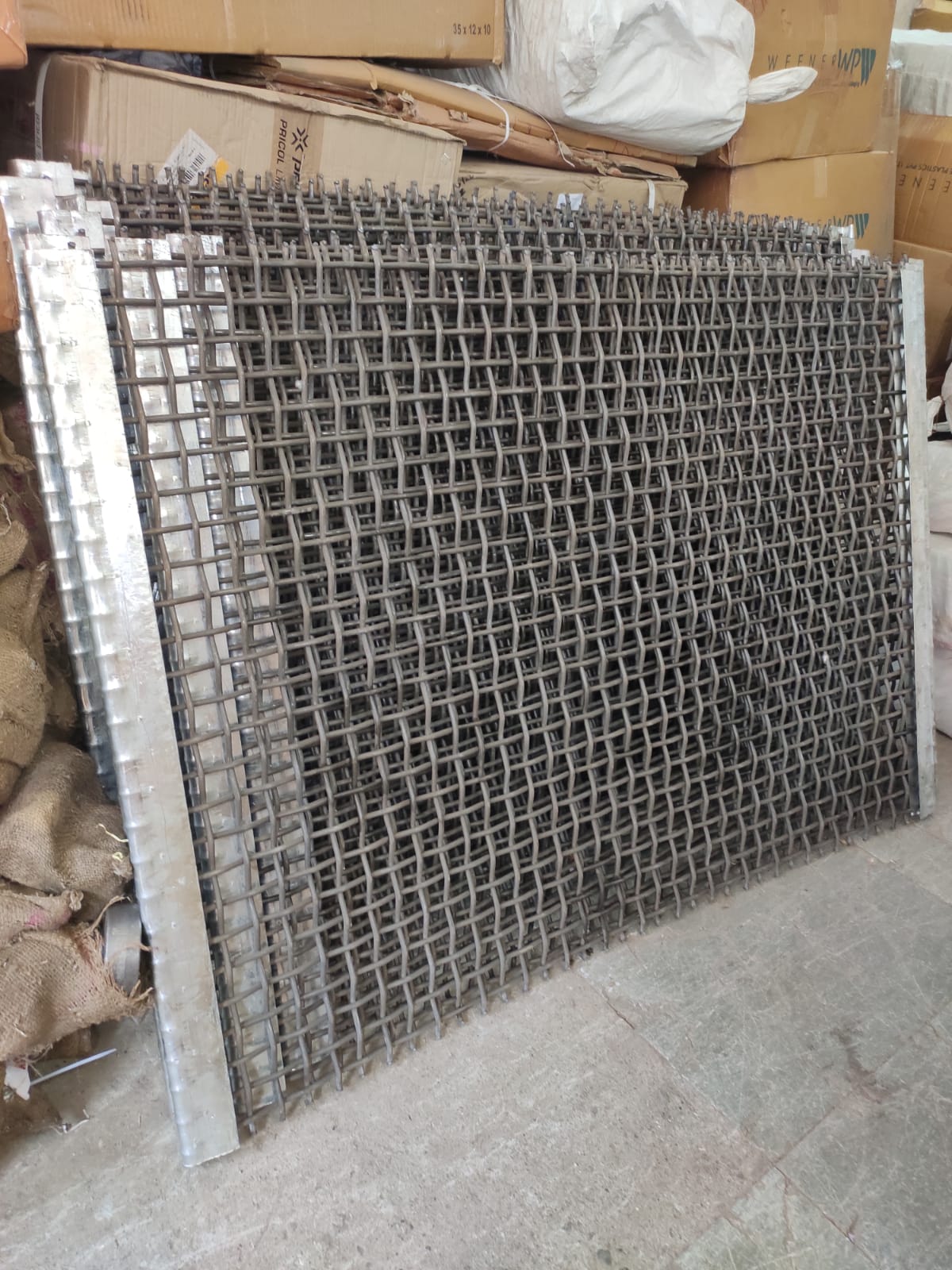

ENROBER CONVEYOR BELT APPLICATION Snacks Industries , Meat Industries Fish Industries , Candy Industries Pizzas Industries , Small Potatoes Industries Bread Industries, Chocolate Industries Vegetables Industries, Biscuits Industries Pastry Industries , Nuts and Fruits Industries HOW TO ORDER 1) METAL 2) MESH PITCH 3) LARGE SPECING 4) WIRE DIA 5) LOCK SPECING 6) TEMP IF 7) WIDTH 8) LENGTH 9) QTY : Laktas wire mesh Company offers many styles and specifications of conveyor belts to suit your specific application and improve your process efficiencies. We provide conveyor belts for industries such as Food Processing, Textiles, Electronics, Agriculture, Automotive, and more. Our first class Customer Service and global presence means we can provide fast and simple distribution around the world.

Send Message