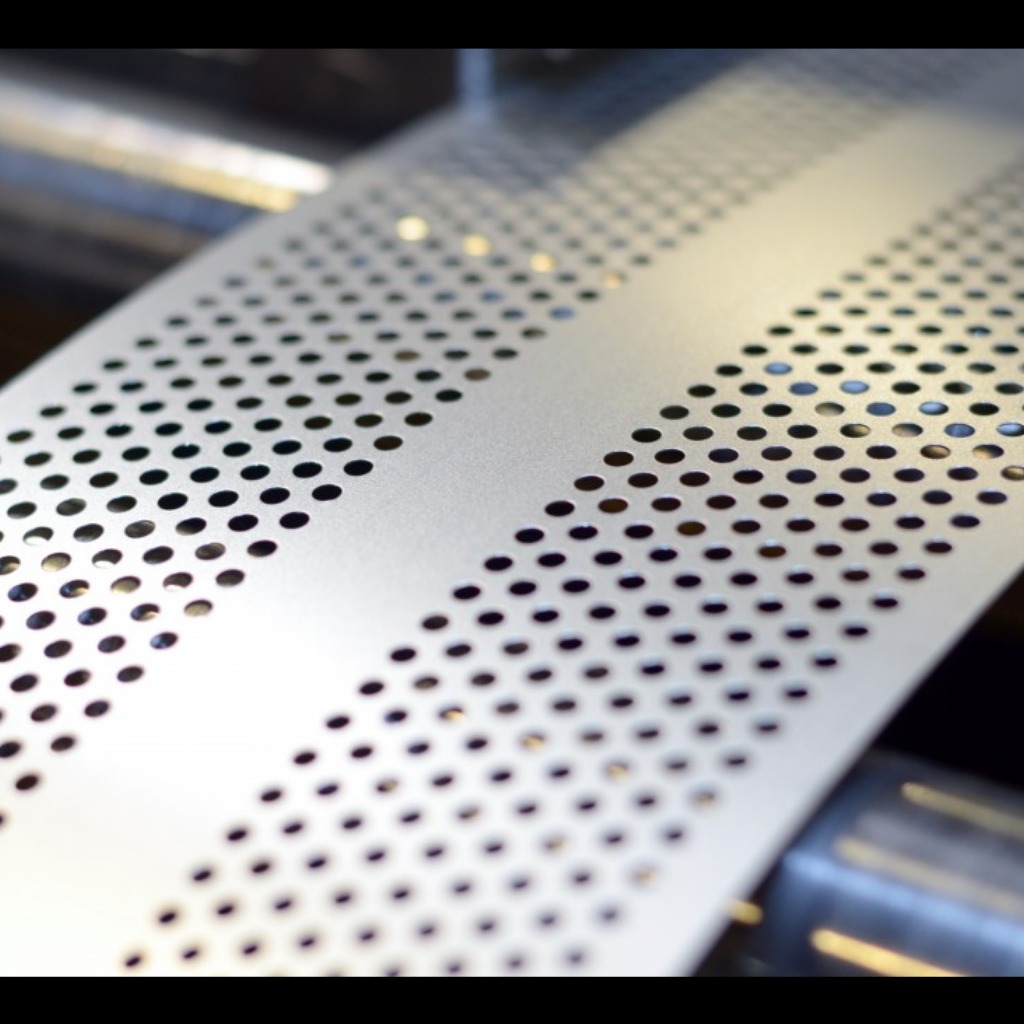

A perforated sheet is a sheet of metal or plastic with holes punched or stamped into it. Perforated sheets are used in many industries, including construction, food, and automotive.

How are perforated sheets made?

Punching: A punch or die presses holes into the sheet

Laser cutting: A laser cuts holes into the sheet

Nibbling: A nibbling machine uses an electrohydraulic motor to punch, cut, and form the sheet

What materials are used to make perforated sheets?

Stainless steel, Aluminum, Brass, Copper, Tinplate, Monel, Inconel, Titanium, and Plastic.

What are the uses of perforated sheets?

Filtering: Perforated sheets can filter light, sound, or fluids

Ventilation: Perforated sheets can be used to ventilate spaces

Decoration: Perforated sheets can be used as decorative elements in architecture

Screening: Perforated sheets can be used as screens in separators, walkways, and sunscreens

Soundproofing: Perforated sheets can be used to reduce sound levels

What are the characteristics of perforated sheets?

Hole type: Perforated sheets can have round, square, elongated, bevelled, fancy, or rhomboid holes

Opening size: The diameter of each punched hole

Overall width: The width of the entire sheet