Construction

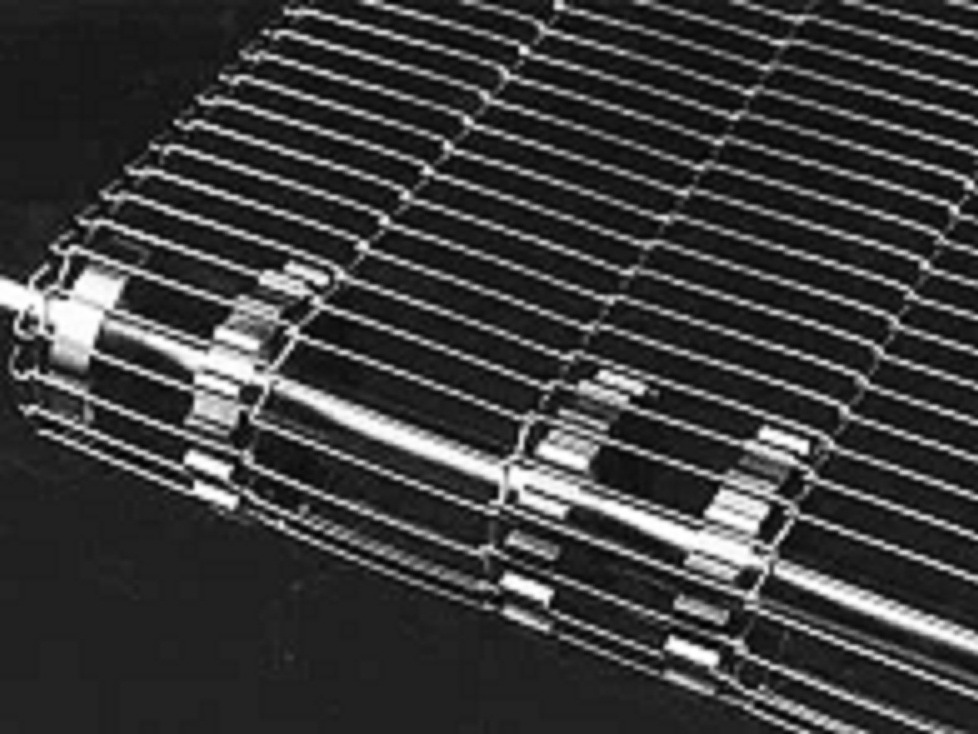

Test sieve wire mesh is made of individual wires woven together to form square openings. The mesh is placed between two die-formed frames.

Precision

Test sieve wire mesh is woven with a precise technique to ensure tight tolerances and accurate openings.

Material

Test sieve wire mesh is typically made of stainless steel or brass. Stainless steel is more durable and corrosion resistant than brass, and is preferred for wet sieving and food and pharmaceutical applications.

Mesh size

Test sieve wire mesh can have an opening range of 4" (100mm) to 635 mesh (20um).

Mesh number

The mesh number is determined by counting the number of openings in one linear inch of the screen. For example, a 4-mesh screen has four square openings per inch.

Use

Test sieves are used to separate particles in a material sample to determine their average size and the quality of a production line.

Industry standards

There are industry standards that dictate the types and specifications of test sieves that should be used.

Stacking

Sieves with different mesh openings are often stacked on top of each other to separate particles by size.

Keywords

635 mesh

Mesh size

wet sieving

Mesh number

Test sieves

average size

4-mesh screen

opening range

material sample

Stacking Sieves

production line

stainless steel

one linear inch

tight tolerances

individual wires

precise technique

accurate openings

Industry standards

four square openings

Test sieve wire mesh

two die-formed frames

different mesh openings

pharmaceutical applications