Welded mesh offers several advantages over traditional MS bar grids when used in flooring applications:

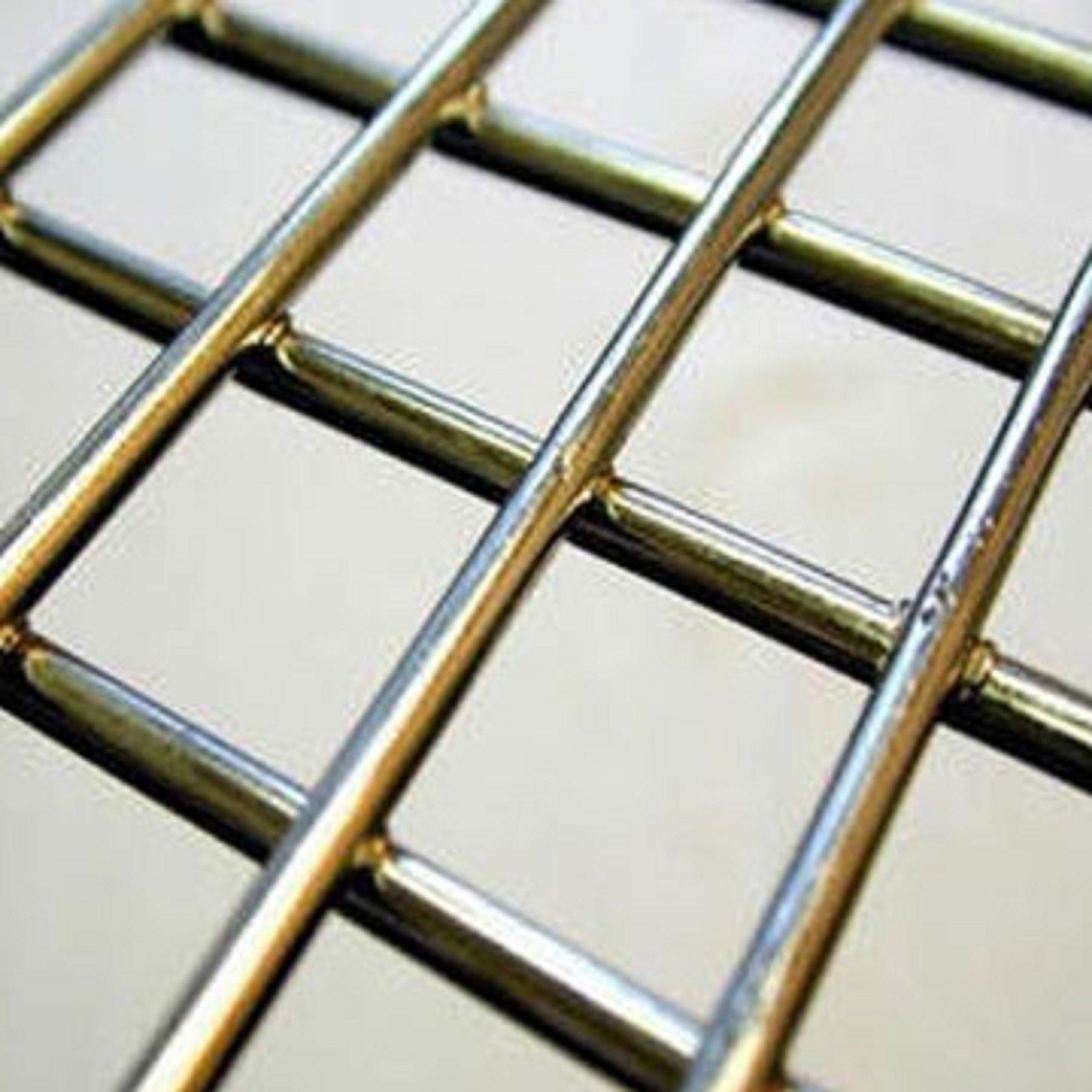

1. Strength & Stability: Welded mesh is created by welding steel wires at intersections, forming a rigid grid that provides excellent load-bearing capacity.

2. Ease of Installation: Unlike MS bar grids, which require manual tying and alignment, welded mesh comes pre-fabricated, reducing labor time and effort.

3. Durability: Welded mesh can be galvanized or PVC-coated, making it more resistant to corrosion and environmental wear compared to untreated MS bar grids.

4. Uniformity: The consistent spacing and welding of the mesh ensure uniform strength distribution, reducing weak points in flooring.

5. Cost Efficiency: Since welded mesh is pre-manufactured, it minimizes material wastage and speeds up construction, leading to cost savings

Here are some key points from the technical data sheet on welded wire mesh panels:

1. Material Composition: The mesh is made of galvanized steel wire, which undergoes a hot-dip galvanizing process to enhance corrosion resistance.

2. Physical Properties:

o Tensile Strength: 435-480 MPa

o Elongation: 20-25%

o Hardness: 150-170 HV1

3. Dimensions:

o Wire diameters range from 2.5 mm to 3.4 mm.

o Mesh sizes vary, with common configurations like 66x68mm, 100x100mm.

4. Coating: A thin zinc layer (0.020-0.030mm thick) is applied to prevent corrosion.

5. Applications: Used for flooring, construction, agriculture, fencing, gardening, and machine protection.

6. Storage Recommendations: Should be stored in dry, closed conditions below 50°C, protected from moisture and direct sunlight.

Here's a comparison between welded mesh and traditional MS bar grids based on specifications:

1. Material Composition

• Welded Mesh: Made from galvanized steel, stainless steel, or mild steel with a protective coating.

• MS Bar Grid: Made from mild steel bars, which may require additional coatings to prevent corrosion.

2. Strength & Durability

• Welded Mesh: Has high tensile strength (435-480 MPa) and uniform load distribution due to welded intersections.

• MS Bar Grid: Strength depends on bar thickness and spacing; requires manual tying, which can create weak points.

3. Corrosion Resistance

• Welded Mesh: Often galvanized or PVC-coated, offering better corrosion resistance.

• MS Bar Grid: Susceptible to rust unless treated with paint or coatings.

4. Installation & Handling

• Welded Mesh: Pre-fabricated panels, easy to install, reducing labor time.

• MS Bar Grid: Requires manual tying and alignment, increasing labor costs.

5. Cost Efficiency

• Welded Mesh: Lower material wastage, faster installation, reducing overall costs.

• MS Bar Grid: Higher labor costs due to manual assembly.

6. Applications

• Welded Mesh: Used in flooring, construction, fencing, agriculture, and machine protection.

• MS Bar Grid: Primarily used in reinforced concrete structures.

Keywords

34 mm

25 mm

elongation 2025

pvccoated offering

bar thickness

50c protected

common configurations

key points

cost savings

construction leading

consistent spacing

pvccoated making

rigid grid

intersections forming

welded mesh

mild steel

galvanized steel wire

welding steel wires

alignment welded mesh

welded mesh offers

mild steel bars

mesh sizes vary

reinforced concrete structures

require additional coatings

direct sunlight heres

dry closed conditions

wire diameters range

hotdip galvanizing process

technical data sheet

minimizes material wastage

environmental wear compared

require manual tying