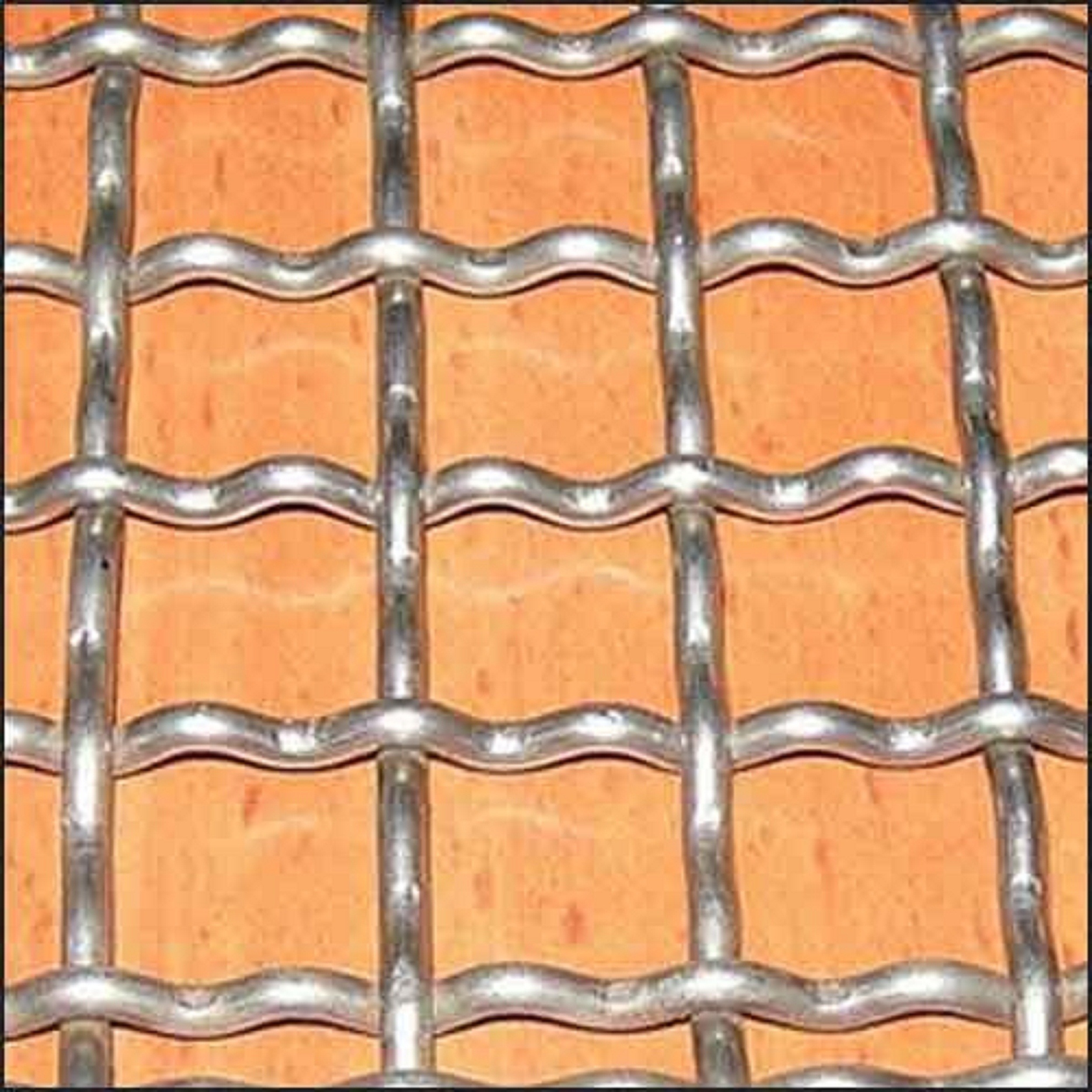

Benefits of Using Crimped Wire Mesh in Flooring

1. High Load-Bearing Capacity

o The crimped structure gives the mesh enhanced rigidity and strength.

o Suitable for walkways, platforms, catwalks, and heavy-duty industrial floors.

2. Slip Resistance

o The textured surface offers better grip than flat metal sheets, reducing the risk of slipping.

3. Good Drainage and Ventilation

o Allows water, dust, or small debris to fall through—ideal for outdoor use or processing plants.

4. Durability

o Often made from stainless steel, galvanized steel, or carbon steel, which are corrosion-resistant and long-lasting.

5. Cost-Effective and Lightweight

o Lighter than solid flooring panels and easier to handle during installation.

6. Aesthetic Appeal (in architectural use)

o Can be used in modern architecture as decorative flooring or ceiling panels.

Crimped wire mesh can be used in reinforcement, but it's not typically used as a primary reinforcement in structural concrete like rebar or welded wire mesh. However, it has specific niche applications in reinforcement contexts. Here's how:

________________________________________

✅ Uses of Crimped Wire Mesh in Reinforcement

1. Plaster and Rendering Reinforcement

• Provides a mechanical key for plaster or stucco to adhere to.

• Helps control cracking and improve the structural integrity of surface coatings.

• Common in walls, ceilings, and curved surfaces.

2. Lightweight Concrete Structures

• Used in precast panels, lightweight partitions, or non-structural concrete forms.

• Helps distribute shrinkage stresses and minor loads.

3. Rock and Tunnel Support (Shotcrete Reinforcement)

• Installed over rock surfaces in mining or tunneling.

• Crimped mesh holds the shape and supports the shotcrete during application.

4. Floor Screed Reinforcement

• In industrial or commercial floors where only light to moderate reinforcement is needed.

• Prevents surface cracking and improves load distribution in top layers of floors.

5. Composite Structures

• Used as part of composite panels where mesh is embedded in sandwich-type materials.

• Enhances shear strength and bonding between layers.

________________________________________

Limitations

• Not suitable for heavy structural loads — it lacks the tensile strength and bonding characteristics of rebar.

• Mesh openings may not meet code requirements for spacing or bar diameter in structural concrete.

• Deformation (crimp) may interfere with concrete cover or cause placement issues.

________________________________________

Summary

Application Suitability of Crimped Wire Mesh

Structural concrete (beams, slabs, columns) * Not recommended

Plaster/render/stucco reinforcement * Very effective

Shot crete support in tunnels/mines * Commonly used

Light-duty floor screeds * Useful

Precast or lightweight panels * Can be effective

Keywords

bonding characteristics

tensile strength

reinforcement 1 plaster

lightweight panels

tunnelsmines commonly

concrete cover

bar diameter

commercial floors

rock surfaces

walls ceilings

mechanical key

modern architecture

longlasting 5 costeffective

carbon steel

fall throughideal

small debris

water dust

moderate reinforcement

rendering reinforcement

primary reinforcement

composite panels

structural integrity

structural concrete

top layers

decorative flooring

crimped structure

layers ________________________________________ limitations

rebar mesh openings

solid flooring panels

recommended plasterrenderstucco reinforcement

reinforcement contexts heres

crimped wire mesh

heavy structural loads

welded wire mesh

mesh enhanced rigidity

lightduty floor screeds

meet code requirements

improves load distribution

surface coatings common

helps control cracking

specific niche applications

textured surface offers

walkways platforms catwalks