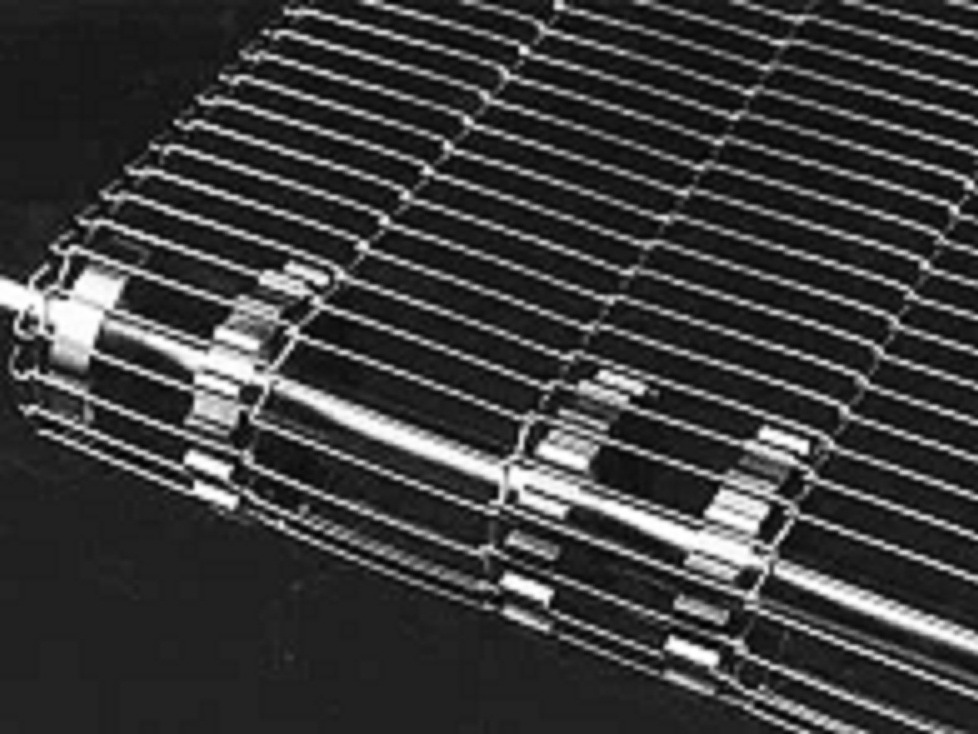

Manufacturing Of Honeycomb Belts Is An Economical And General Use Belt, Widely Used In Medium Load Applications Ranging From 40 To 1500 Degrees F. These Belts Are Primarily Suitable For Unstable Items Needing Very Flat Surfaces And Considerable Product Support. This Is Certainly The Most Commonly Used Wire Mesh Conveyor Belt. These Belts Are Very Economical For Medium Temperature And Load Conditions And Also Fit Well Into Any Budgets Of Companies. This Is Also A Functional Belt For Small Pulleys. The Balanced Mesh Features A Simple Yet Effective Design, Constructed From Alternating Left And Right Hand Spiral Coils. These Coils Are Held In Place By Interconnecting Crimp Rods Which Run Through The Width Of The Belt. Also, These Belts Require Less Maintenance And If The Belt Is Ever Damaged, The Damaged Section Can Be Easily Replaced With Minimum Efforts.

Applications

Heat Treatment

Food Industries

Automotive Industries

Glass Industries

Cement Industries

Keywords

Left

Width

Place

Budgets

Companies

Crimp Rods

Manufacturing

Small Pulleys

Unstable Items

Honeycomb Belts

Minimum Efforts

Damaged Section

Load Conditions

Functional Belt

General Use Belt

Less Maintenance

The Balanced Mesh

Cement Industries

40 To 1500 Degrees

Very Flat Surfaces

Medium Temperature

Wire Mesh Conveyor Belt

Right Hand Spiral Coils

Medium Load Applications

Simple Yet Effective Design

Considerable Product Support

Applications

Heat Treatment

Food Industries

Automotive Industries

Glass Industries